One of the main advantages of FDM / FFF 3D printing technology is the wide selection of 3D printing material types. In contrast to, for example, powder technologies such as SLS or MJF, where the choice of materials is limited to just a few grades, the FDM / FFF method allows for the use of dozens of highly differentiated plastics in terms of properties, being additionally reinforced, what significantly influences their properties.

Spectrum Filaments offers one of the widest ranges of materials for 3D printing. In this article, we describe three types of filaments based on ASA material:

- ASA 275™,

- ASA-X CF10™,

- ASA Kevlar.

While they share many common features, each of them has its unique advantages that make it the right choice for specific applications.

ASA (Acrylonitrile Styrene Acrylate) is a synthetic material that has gained wide recognition among 3D printer users in recent years. It is a derivative of ABS, one of the most popular thermoplastics used in both industry and 3D printing itself. Both materials share many common features, but there are significant differences that determine their unique properties and applications. The most significant advantage of ASA is its resistance to UV radiation and other atmospheric factors. Thanks to the addition of acrylate, ASA is more resistant to color fading and degradation caused by prolonged exposure to sunlight. This features make ASA filament an ideal material for the production of items that will be exposed to outdoor weather conditions, such as exterior parts of cars or components and enclosures of devices operating outside.

Spectrum Filaments manufactures three ASA-based filaments:

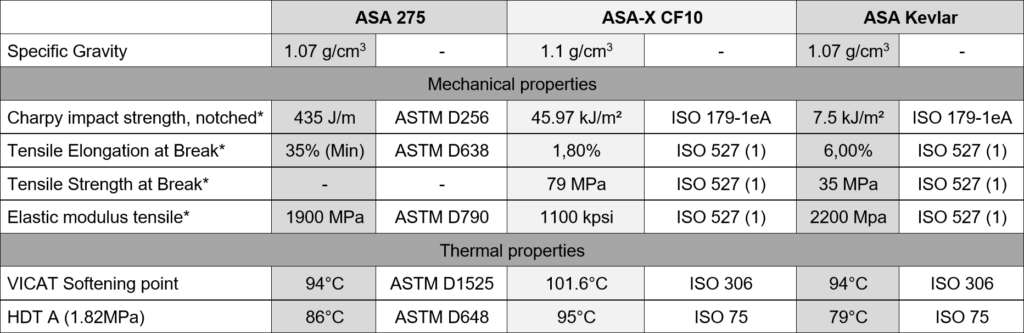

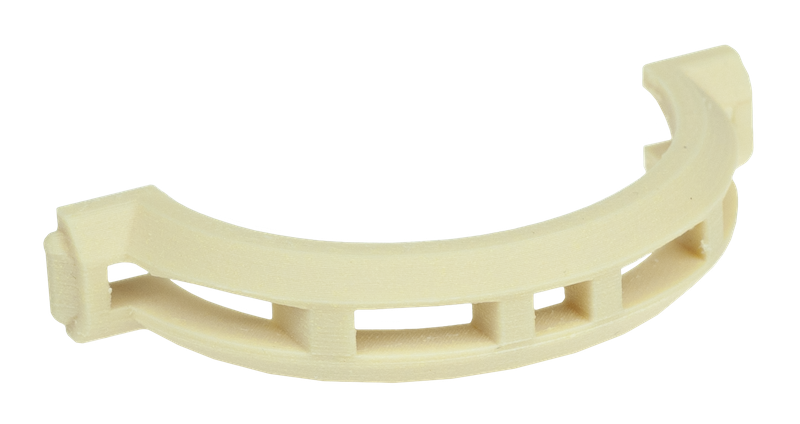

ASA 275™ filament is a professional material designed for use on 3D printers of all classes – amateur, desktop, and industrial. It does not require a closed build chamber, and it can be processed at lower temperatures compared to ABS: 220-245°C for the nozzle (only slightly higher than PLA) and 60-80°C for the print bed. In the case of desktop printers like Creality Ender 3, Prusa Mk3/Mk4, or Mini, the only significant addition can be used in the case of 3D printing of very large parts are adhesive agents, to prevent the first layers from detaching from the build plate.

When it comes to applications, ASA 275™ is the perfect choice for 3D printing of prototypes, functional production tools, and components that need to withstand changing weather conditions.

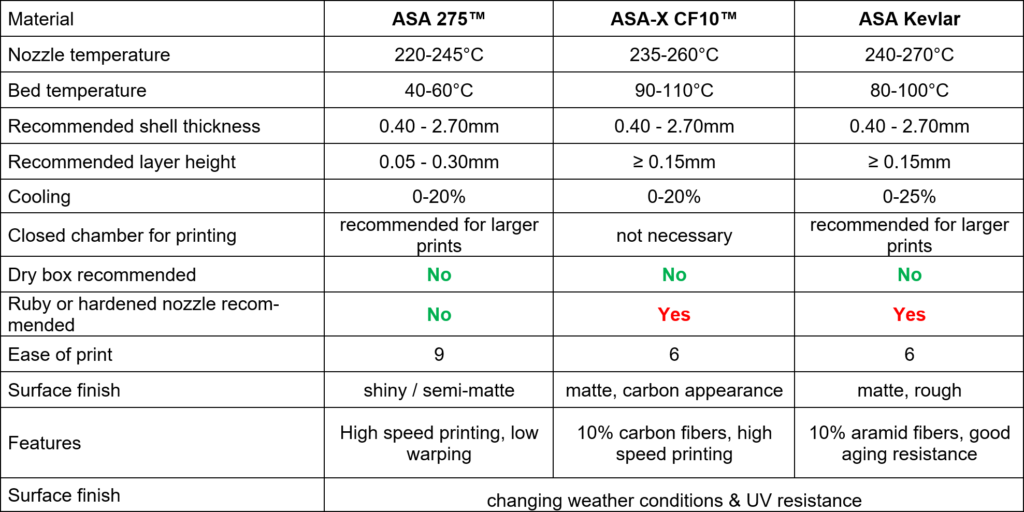

ASA-X CF10™ is a composite material that combines ASA with carbon fibers, ensuring high mechanical properties for 3D printed models. The filament is exceptionally resistant to sunlight exposure (UV) and humidity (hydrolysis), as well as provides very good impact strength. ASA-X CF10™ requires slightly higher temperatures for 3D printing – nozzle at 235-260°C and the print bed at 90-110°C. Similar to ASA 275™, ASA-X CF10™ exhibits low shrinkage and does not require a closed build chamber. The material has a matte finish and a characteristic carbon surface.

It finds application in the same areas as ASA 275™, but it guarantees higher temperature resistance (HDT A: 95°C, VICAT: 101.6°C) and is more resistant to impacts and cracking.

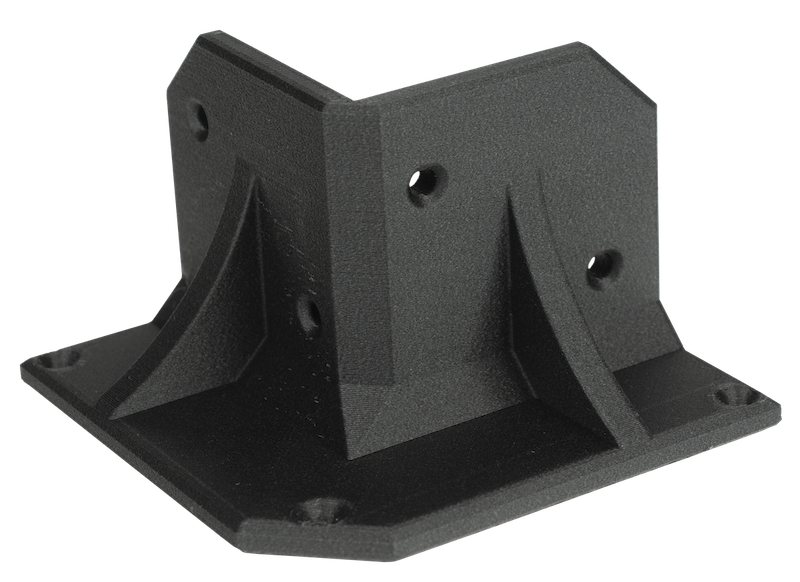

ASA Kevlar is a technical composite material that combines ASA with aramid fibers (Kevlar). Aramid fibers possess a very high tensile strength, making them ideal for various special applications such as helmets, gloves, sports and sailing equipment. The ASA Kevlar reinforcement gives this material unparalleled durability against damage while still being relatively easy to 3D print due to low shrinkage and processing temperatures. Similar to ASA-X CF10™, it is not recommended for use on entry-level hobbyist 3D printers but it can be successfully used on other desktop printers as it does not require a closed build chamber (although using one improves the efficiency of 3D printing, especially for larger and more geometrically complex 3D prints). The recommended temperature range for the nozzle is 240-270°C, and for the print bed: 80-100°C. Parts 3D printed from this filament have increased temperature resistance, although slightly lower than ASA-X CF10™ (HDT B: 89°C, VICAT: 94°C).

Where should be Spectrum ASA filaments used and how do they complement each other?

Each of these materials has its unique advantages, making them suitable for different applications. ASA 275™ is the easiest to process and the most cost-effective material among the three. It will work well on any 3D printer for the production of prototypes, manufacturing tools, or parts exposed to sunlight, various weather conditions, or UV radiation (e.g., in laboratories). Regardless, it is an excellent alternative to ABS, having lower shrinkage and processing temperatures, while maintaining practically the same mechanical and temperature resistance values.

ASA-X CF10™ is an ideal choice for projects that require high mechanical resistance along with resistance to weather conditions. It is also worth noting its high temperature resistance compared to other thermoplastics. ASA Kevlar, on the other hand, is suitable for applications where parts need to exhibit exceptional resistance to damage and be difficult to break or crack.

The choice between these three materials will depend on your specific needs. If you are looking for a relatively inexpensive material that is resistant to UV radiation and easy to print, ASA 275™ would be the best possible choice. If you need a material with high resistance to weather conditions, good mechanical properties, and high temperature resistance, you should consider purchasing ASA-X CF10™. On the other hand, if you are looking for a material that is “bulletproof” and difficult to break, it will be hard to find a better option than ASA Kevlar.

Remember, the key to achieving the best results in 3D printing is choosing the right material for your specific application. Therefore, it’s important to understand the differences between these three filaments in order to make the best choice for your project.