Verification of filament quality using the proprietary “Verify Your Spool” system.

Filament for 3D printing is a thermoplastic material with a specific diameter wound onto a spool made of plastic or cardboard. Although it may seem for most people like a simple product to manufacture, producing high-quality filament requires many factors that affect the final outcome, making it a highly demanding process.

The consistent diameter and roundness of the filament are crucial factors affecting the quality and continuity of the 3D printing process, which is why it’s so important to maintain them at a constant level. To achieve this, we have developed an in-house system called “Verify Your Spool,” available exclusively in our offer, which allows for easy verification of the quality of the filament we produce in real-time, giving the end-user the confidence that the product will meet their requirements.

There are many factors that affect the quality of filament, including:

- the quality of raw materials – the base material as well as natural or chemical additives

- chemical composition – proper quantitative selection of individual components that ensures the appropriate final effect of the printed part, while on the other hand providing simple and repeatable operation on the 3D printer

- drying and low humidity – most of the materials used in 3D printing are hygroscopic, meaning that they absorb moisture from the environment. Excess humidity causes material degradation, decreased physical and chemical properties, and ultimately makes the filament difficult to 3D print

- stability of the blend and the superior quality of the individual components of the production line, including the use of control systems at every stage of material manufacturing

- constant diameter and roundness – 3D printing filaments are manufactured in two diameters: 1.75mm and 2.85mm; diameter variation over 0.05mm can make the 3D printing process unstable and cause problems with processing on the 3D printer (in extreme cases, the printing system may become clogged / jammed); the same applies to roundness – the more “round” the filament is, the smoother it is to work with.

Efficient production and maintaining consistent filament values – the key to the quality of the 3D printing process.

To ensure high-quality filament, it is necessary not only to properly compose the formulation, but also to maintain constant values of its diameter, ovality, and homogeneity. In the case of using a 1.75mm diameter filaments, situations where the filament’s diameter suddenly increases, for example, to 2.20mm or drops to 1.30mm, cannot be allowed as this can significantly affect the quality and continuity of the 3D printing process. Similarly, irregularities such as discoloration or non-homogeneity of additives on different parts of the material (e.g., too high concentration of composite material on several consecutive meters of the filament) are unacceptable.

Another important factor is production efficiency. In the case of our company, in addition to using high-performance production lines, they are characterized by excellent technological optimization and the use of advanced measurement systems, which translates into ensuring excellent filament quality.

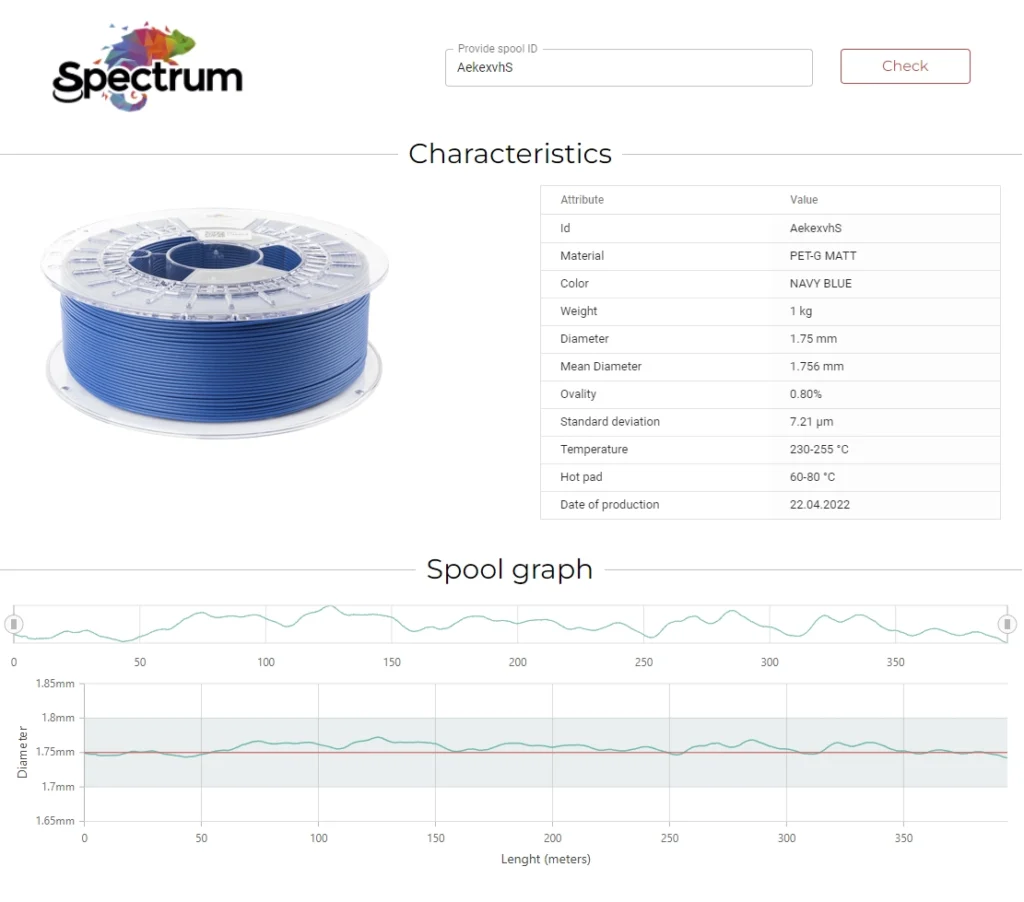

Each spool that leaves our production lines has an individual quality report generated by our proprietary system. During production, our filament is constantly measured in two axes with an accuracy of ±0.8μm. To ensure that the measurement result is reliable, we use certified laser gauges designed by a reputable Swiss company. The information collected by the system includes: diameter variation throughout the whole length of the filament, average diameter, ovality, and standard deviation for each meter of manufactured filament. The data is archived and cataloged in our system. Each manufactured filament spool receives its own identifier, and our system returns a complete set of information online.

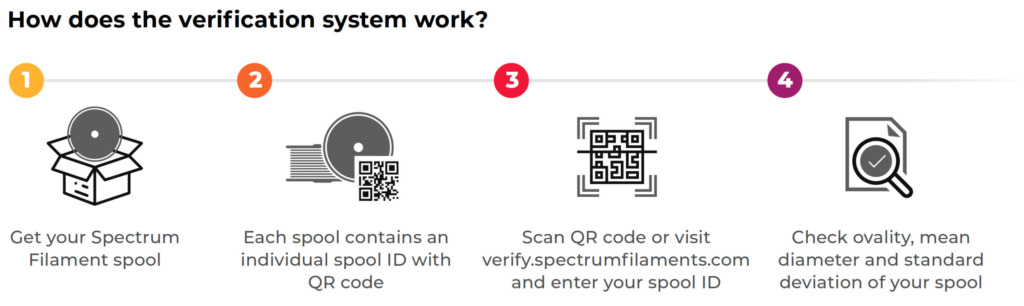

End-customer can check a detailed report on the production of that particular batch by scanning the QR code or by entering the individual spool ID number on the Verify Your Spool page. The report includes, among others, the following information:

- material type and its trade name

- colour

- mean diameter

- average diameter

- ovality

- graph showing fluctuations in diameter and ovality during production, indicating whether it stays within the tolerance limits

- standard deviation

- production date.

Quality you can verify, every spool, every time.

“Verify Your Spool” feature provides indisputable evidence of the superior quality of our filament and confirms that our assurances about its quality are fully justified. Regardless of the number of ordered filament spools – whether it is 5, 500 or 5000 – each of them possesses slightly different yet highly comparable parameters. It can be said that we provide our customers with insight into our internal quality system. We are confident in the quality of our product and encourage our customers to verify it themselves.