SiCeram GmbH, in cooperation with Spectrum Filaments, has developed an innovative series of ceramic materials for 3D printing using FDM/FFF technology! Four specialized filaments are the first such commercial solution on the global market, enabling 3D printing of high-tech ceramics using typical desktop 3D printers.

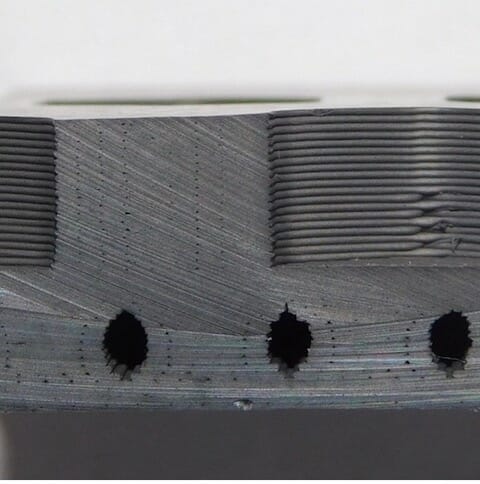

3D printing is a new additive forming technology for ceramic components. It will find application mainly for the manufacture of prototypes, small batches or complex geometries, for example with hollow interior spaces, that cannot be produced by other traditional techniques.

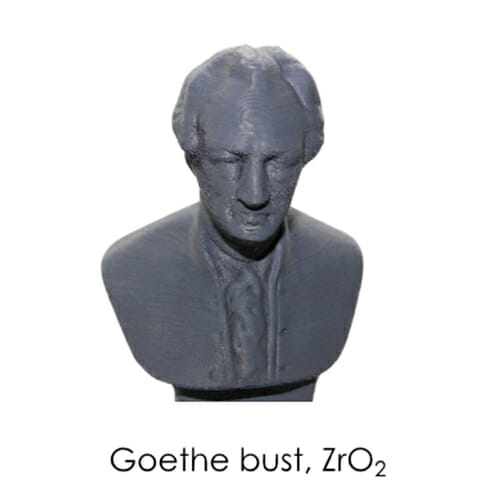

Zirconia

Zirconia is a filament containing zirconium powder of high purity. The use of appropriate organic agents as a binder results in a flexible filament that can be used in classical 3D printers operating in FFF / FDM technology. The organic content of the filament amounts to about 14.0 percent by mass.

Among typical high-performance ceramic materials, ZrO2 has the highest density, at 6.05 g/cm3. ZrO2 has high strength at room temperature and, due to crack-induced transformation, very high fracture toughness. However, compared with Al2O3, the strength decreases dramatically with increasing temperature.

Due to its high coefficient of linear thermal expansion (10*10-6K-1), ZrO2 can be bonded to stainless steel without problems. Corrosion resistance in the range of pH<7 is good, in the range of pH>7 very insufficient. ZrO2 finds application in O2- sensors because of its ionic conductivity.