In the early years of amateur and desktop 3D printing using FDM/FFF technology, the number of available materials was very limited, consisting mainly of a few types of filaments, with PLA and ABS leading the way. Currently, new filaments based on materials such as PET, ASA, or PA have started to enter the market. However, they still serve as supplements to the aforementioned duo – PLA and ABS, which have been the foundations of desktop 3D printing with thermoplastics.

This changed in 2020 when, at the beginning of the COVID-19 pandemic, the global 3D printing community started 3D-printing protective face shields and various other accessories for healthcare and medical services saving victims of the coronavirus. It was then discovered that PET-G – a filament previously perceived mainly as a decorative material due to its transparency and light-diffusing properties – could be successfully used as an engineering material thanks to its numerous unique physical and chemical properties. This sparked a trend for this material, elevating it to the top three most popular filaments on the market, eventually displacing ABS due to its much easier processability on 3D printers.

PET (polyethylene terephthalate) is one of the most popular plastics worldwide. The material was discovered in the 1940s by two British chemists, John Rex Whinfield and James Dickson, who worked for the Calico Printer’s Association of Manchester. Initially, it was primarily used in the textile industry. However, its popularity increased when Nathaniel Wyeth, the brother of renowned artist Andrew Wyeth, invented the PET bottle in the 1970s, which could withstand the pressure of carbonated beverages. Since then, the material gradually began to replace glass in the production of bottles and containers for beverages and all kinds of fluids (cosmetics, cleaning agents, or chemicals).

PET is tough, allows good light transmission, and is also safe for food contact applications. It is widely used in the packaging and textile industries. In the 3D printing sector, it appears in a slightly modified form – a glycol is added to its chemical composition (hence the name PET-G), which improves its processability on 3D printers, giving it the necessary fluidity and flexibility while reducing shrinkage (pure PET is difficult in 3D printing in this regard).

Over time, scientists began to create additional synthetic materials based on polyethylene terephthalate. This led to the development of PCTG, which represents an advancement in polyester technology. It is a blend that is more flexible and impact-resistant. Both PCTG and PET-G materials have their unique properties that make them suitable for different applications.

PET and PCTG – main similarities and differences

PET is primarily used in the production of beverage bottles and textile fibers. The material is very hard, durable, allows good light transmission, and is also safe for food contact. PCTG has excellent properties such as higher transparency, impact resistance, flexibility, ease of molding and processing, as well as suitability for food contact. Due to its hardness and flexibility, PCTG is often used in the production of cosmetics, medical, and food packaging.

Comparing both materials, they share many common features such as high transparency, chemical resistance, and safety in food contact. However, they differ in certain physical properties:

- • PET has excellent gas barrier properties, making it ideal for beverage packaging that needs to be airtight and CO2-resistant. PET is also more widely used in general.

- • PCTG exhibits better flexibility and impact resistance than PET, making it more suitable for applications, where frequent use or exposure to impacts is expected. Additionally, PCTG is easier to process, providing greater freedom in shaping the geometry.

When it comes to 3D printing, the simplest distinction between the two materials can be summarized as follows:

- • PET-G is one of the most popular, affordable, and easy-to-print 3D filament. It can be printed on any FDM/FFF 3D printer as long as it can heat the print nozzle up to 260°C and has a heated build plate (both of which are commonly standard features). PET-G exhibits minimal shrinkage and does not require a closed build chamber. However, it tends to have stringing issues, making it problematic when using larger diameter nozzles (0.6-0.8mm).

- • PCTG is a more specialized and high-performance version of PET-G, suitable for creating more durable applications. It is particularly useful when higher chemical resistance is required, and traditional PET-G may not provide sufficient mechanical strength and impact resistance. PCTG is printed at comparable but slightly higher temperatures at 250-270°C.

PCTG Filaments

Spectrum Filaments offer includes filaments based on PCTG material. The filaments come in three different grades:

- PCTG Premium – a material in its pure form, adapted to easy 3D printing,

- PCTG GF10 – doped with 10% glass fiber,

- PCTG CF10 – doped with 10% carbon fiber.

Spectrum PCTG Premium is as easy to 3D print as PET-G, but it requires slightly higher operating temperatures, typically ranging from 240-270°C for the print nozzle and 60-80°C for the build plate. This may pose some challenges for entry-level 3D printers like the Creality Ender 3, as it operates at the upper limits of their temperature capabilities. Therefore, while it is possible to use PCTG with the Ender 3, it is more suitable for experienced users rather than beginners. For desktop-class 3D printers such as BambuLab, Prusa, or Raise3D, users should not encounter any difficulties.

The advantage of Premium PCTG filament is its increased impact resistance, high dimensional stability, low shrinkage, and temperature resistance up to 76°C. 3D prints made with PCTG exhibit excellent surface quality and higher rigidity (but they are not flexible or elastic). Similar to PET-G, PCTG has high chemical resistance for printed parts.

Another important feature is the wide range of color options available, including highly transparent variants that effectively scatter light. PCTG comes in the following colors:

- Solid: white, yellow, orange, red, light green, light blue, navy blue, silver metallic, grey, black

- Transparent: clear, yellow, orange, red, green, blue.

However, it’s important to note that in 3D printing, we don’t achieve full transparency but rather “translucency” – the more outlines or thicker the walls, the lower the transparency. The translucency effect is much better with PCTG compared to regular PET-G.

Spectrum PCTG GF10 is a composite material based on PCTG doped with 10% glass fiber, which exhibits much higher strength and an atypical matte surface for materials of this type. It has high stiffness and hardness, as well as higher wear resistance than standard Premium PCTG. Due to its strong interlayer adhesion and low shrinkage, it allows for the printing of large prints, even on entry-level 3D printers (considering the limitations described above).

Glass fiber reinforced materials tend to cause wear on 3D printer nozzles. Therefore, in formulating the filament composition, functionalized glass fibers with less aggressive geometry were used. Additionally, the glass fibers give the printed parts a unique structure, which not only enhances aesthetics but also increases their usability. The filament also exhibits slightly higher temperature resistance, with an HDT B of 78°C and VICAT temperature of 89°C.

The material has the same 3D printing parameters as Premium PCTG and is processed at the same temperatures.

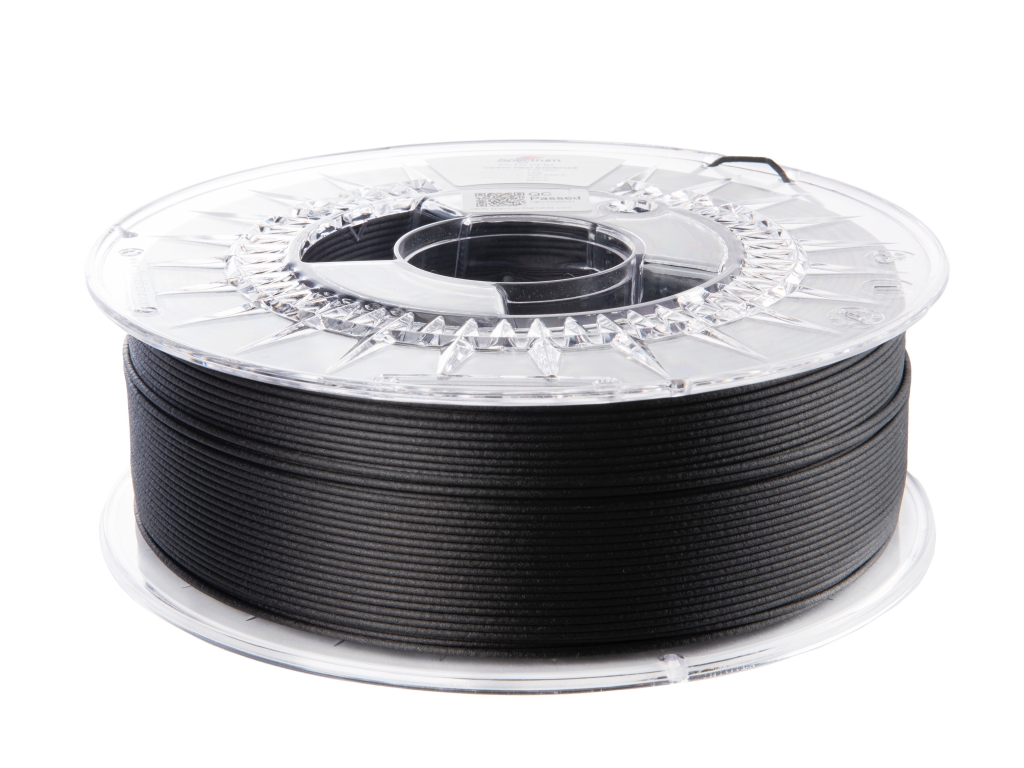

Spectrum PCTG CF10 is a composite material based on PCTG doped with 10% carbon fiber, which imparts exceptionally high stiffness to the filament while limiting the brittleness typically associated with other carbon fiber composites based on PET-G. PCTG CF10 enables the 3D printing of parts with increased hardness and tensile strength compared to pure PCTG or PET-G. The use of carbon fibers enhances the thermal resistance of the filament, further reduces shrinkage, and gives it a distinctive matte appearance.

In terms of temperature resistance, PCTG CF10 has the same parameters as PCTG GF10 and is printed using similar 3D printer settings. However, when using carbon fiber reinforced filament, there is a risk of standard print nozzles degrading over time. Therefore, it is recommended to consider replacing them with steel nozzles before starting the printing process.

When to use a specific Spectrum PCTG filament:

- If you need to use PET-G for part production but require higher physical or impact resistance parameters, use PCTG Premium.

- If the part needs to be transparent or colored, use PCTG Premium.

- If the part does not need to be transparent or colored but requires stiffness and higher durability, use PCTG GF10 or PCTG CF10.

- If the part needs to be more wear-resistant, use PCTG GF10.

- If the part needs to be rigid and hard, use PCTG CF10.