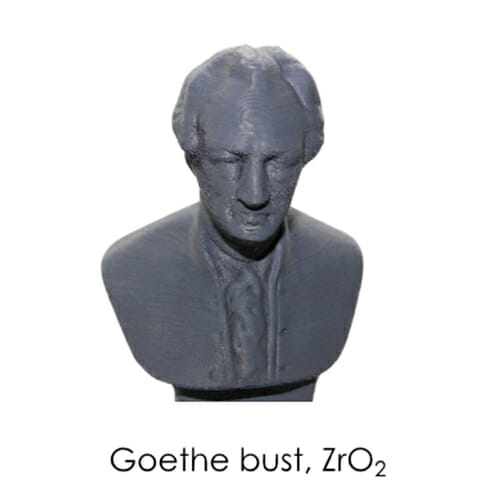

SiCeram GmbH, in cooperation with Spectrum Filaments, has developed an innovative series of ceramic materials for 3D printing using FDM/FFF technology! Four specialized filaments are the first such commercial solution on the global market, enabling 3D printing of high-tech ceramics using typical desktop 3D printers.

3D printing is a new additive forming technology for ceramic components. It will find application mainly for the manufacture of prototypes, small batches or complex geometries, for example with hollow interior spaces, that cannot be produced by other traditional techniques.

Silicon nitride

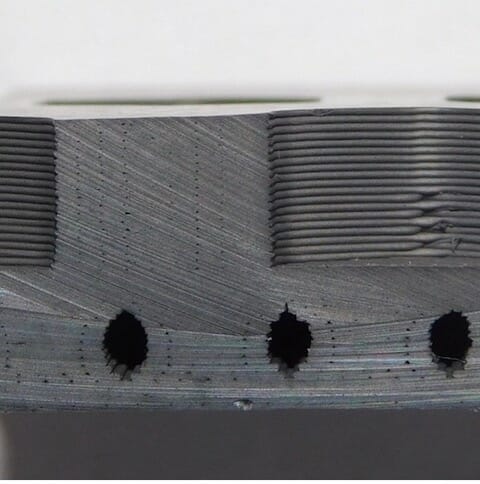

Silicon nitride filament contains ceramic powder of high purity. The use of appropriate organic agents as a binder results in a flexible filament that can be used in classical 3D printers operating in FFF/FDM technology. The organic content of the filament amounts to about 21.5 percent by mass.

Si3N4 exhibits higher strength and fracture toughness than SSiC. The very low coefficient of linear thermal expansion results in high resistance to thermal shock. Si3N4 is an electrical insulator, and its thermal conductivity is 30 W/mK (25% of SSiC).

The wettability of Si3N4 by nonferrous metals and glass castings is very low, which qualifies it as a tool material. The maximum operating temperature is in the range of 1,300 ? 1,400°C. Due to sintering additives based on oxide, alumina and yttrium, corrosion resistance is good only in the acidic range (pH < 7).