Filament ASA 275 finds applications in various fields, including the production of fixtures and the creation of end-use parts. In today’s case study, we will explore specific application, presenting the experiences of our customer, Z_CAD_SK, in the automotive industry, specifically in the field of car tuning. It is important to emphasize that the presented solutions are used exclusively in prototypes of car projects and are not intended for use on public roads or in uncontrolled conditions. These vehicles differ significantly from standard models, undergoing numerous modifications, ranging from engine components to chassis and body elements. Our customer shares his experiences with us regarding the use of our filaments in these unconventional applications.

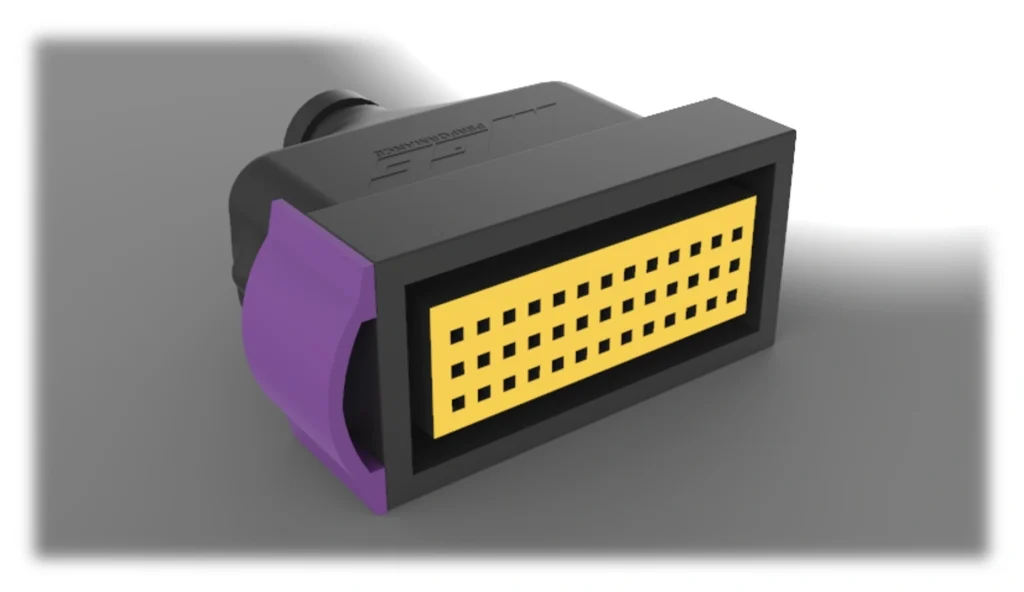

But what exactly “fixture” is? In the assembly of electronic components, the concept of “fixtures” refers to special devices, tools, or structures that allow for the proper securing, supporting, or stabilizing of objects or components in a specific position to carry out specific operations or measurements. Due to ergonomic considerations and the challenging access to the assembly of individual electronic components, such as wire harnesses, fixtures can have complex shapes and may be exposed to loads in various directions. One of the applications of our Filament ASA 275 is the modification of a connector (see Figure 1) along with an enclosure serving as a fixture, facilitating the assembly and disassembly of the connector.

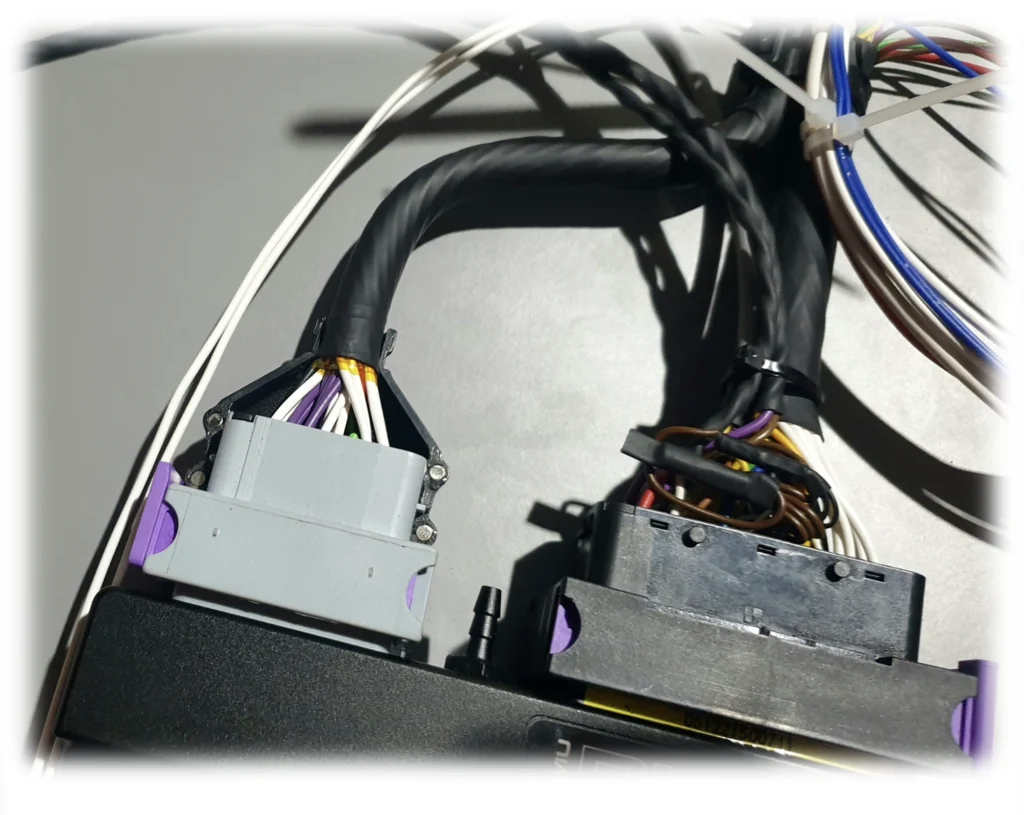

This modification protects the wires from being pulled out of the connector when disconnected from the control unit and dampens light loads generated during bending and shifting of wires during vehicle maintenance. For this purpose, our client utilized our Filament ASA 275, which proved suitable for creating the thin-walled part of the connector. The material’s strength, combined with its flexibility, made it an excellent choice for securing wires, especially during connector connection and disconnection (see Figure 2).

Filament ASA 275 serves as a valuable tool that can be effectively utilized in innovative projects, not only in the automotive industry but also in various other industrial sectors. We encourage you to get in touch with our team if you are interested in using our filaments in your projects or require professional assistance in their implementation.

Furthermore, if you wish to share your ideas for practical applications of our filaments, please contact us at office@spectrumfilaments.com. Selected projects will be rewarded with filament spools or promotional merchandise. We look forward to receiving your inspiring ideas!