PELLET SELECTION & DEHUMIDIFYING

Before the production begins, all starts with choosing the highest quality of polymer. Additionally, the basis of the whole proces is a professional plastic processing knowledge. The polymer used for filament manufacturing is delivered as a colorless pellet. Extremely sensitive granulate particles should be carefully dried before extrusion. To dehumidify pellet is transported to a drying system using pneumatic feeders.

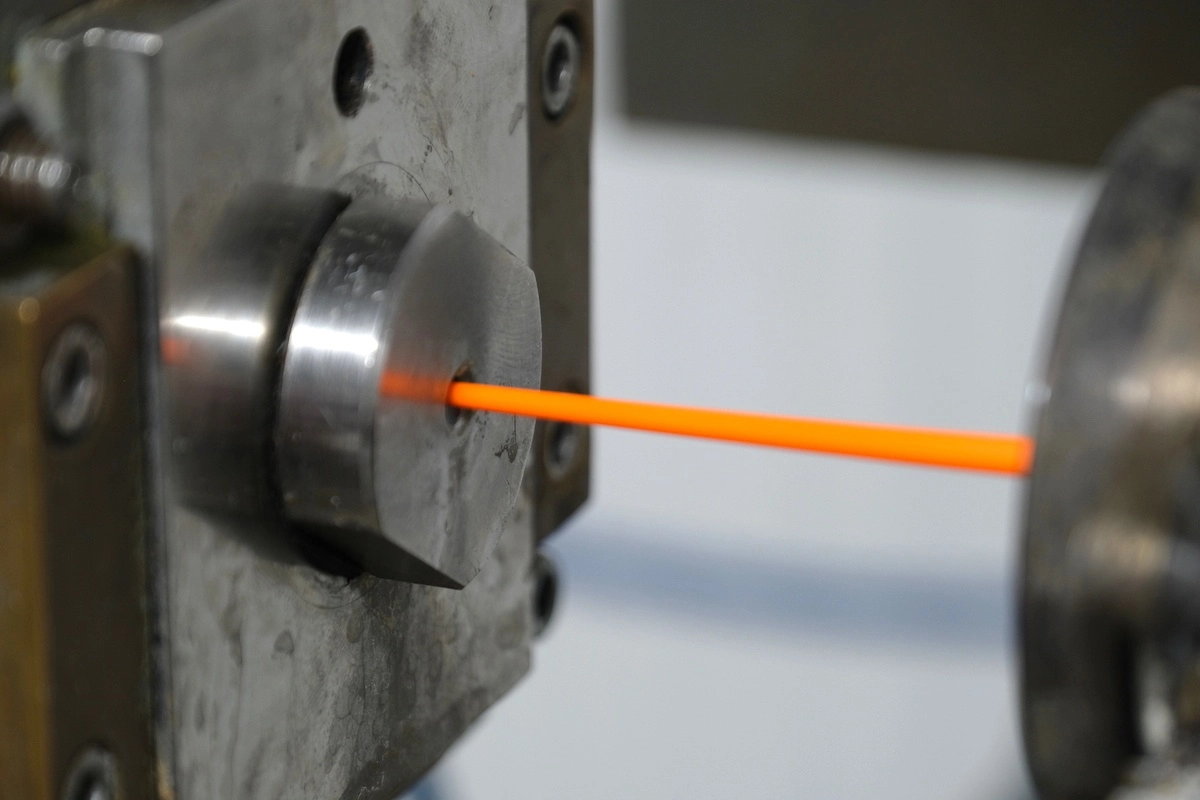

EXTRUSION

The extruder is a key line element responsible for homogenization of the polymer. Pellet goes through several heated zones transported by plastification screw. That process allows material to melt and blend with color pigment or other additives. Controlled pressure is demanded to achieve homogeneous filament and constant diameter of final product.

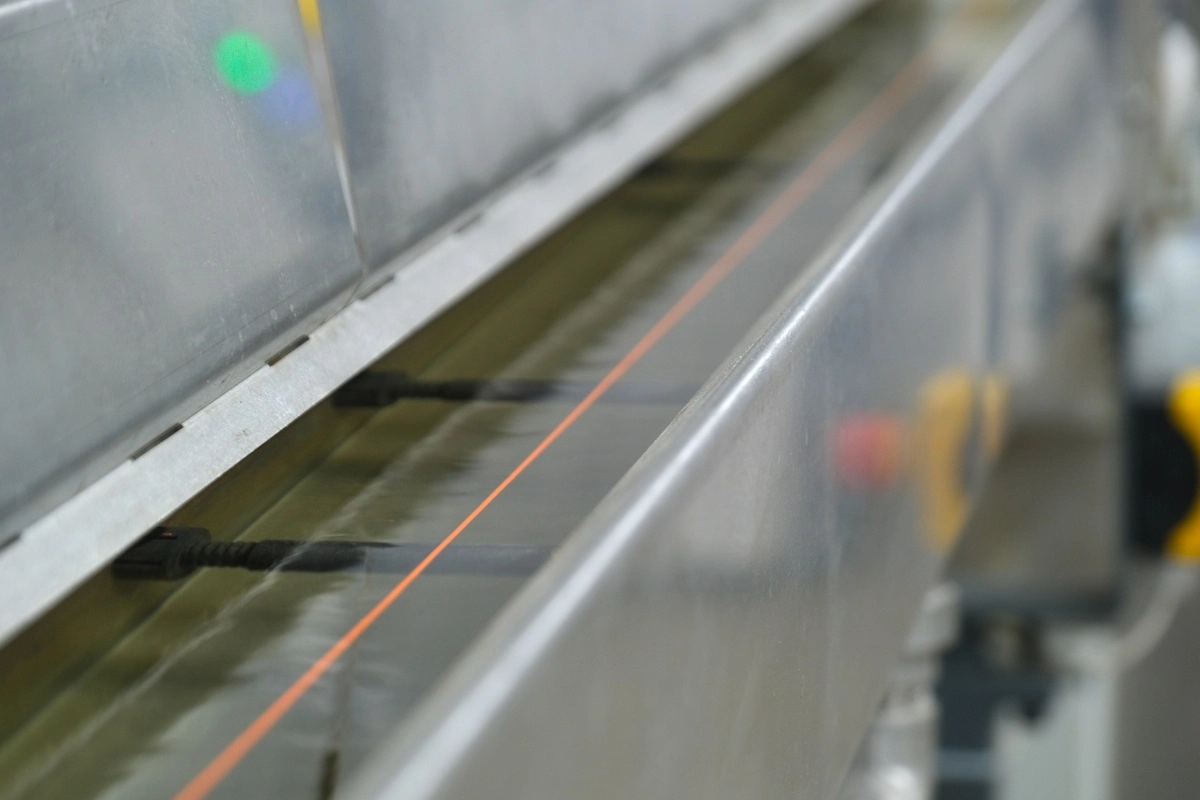

COOLING

Cooling is a truly important part of the whole production process. It is necessary to sustain temperature and purity of coolant, since those have significant influence on the final product. First cooling step called “warm” bath prevents uncontrolled shrinkage of the material and surface quality. In the final step filament is fed into the cold water bath allowing efficient discharge of the heat from strand.

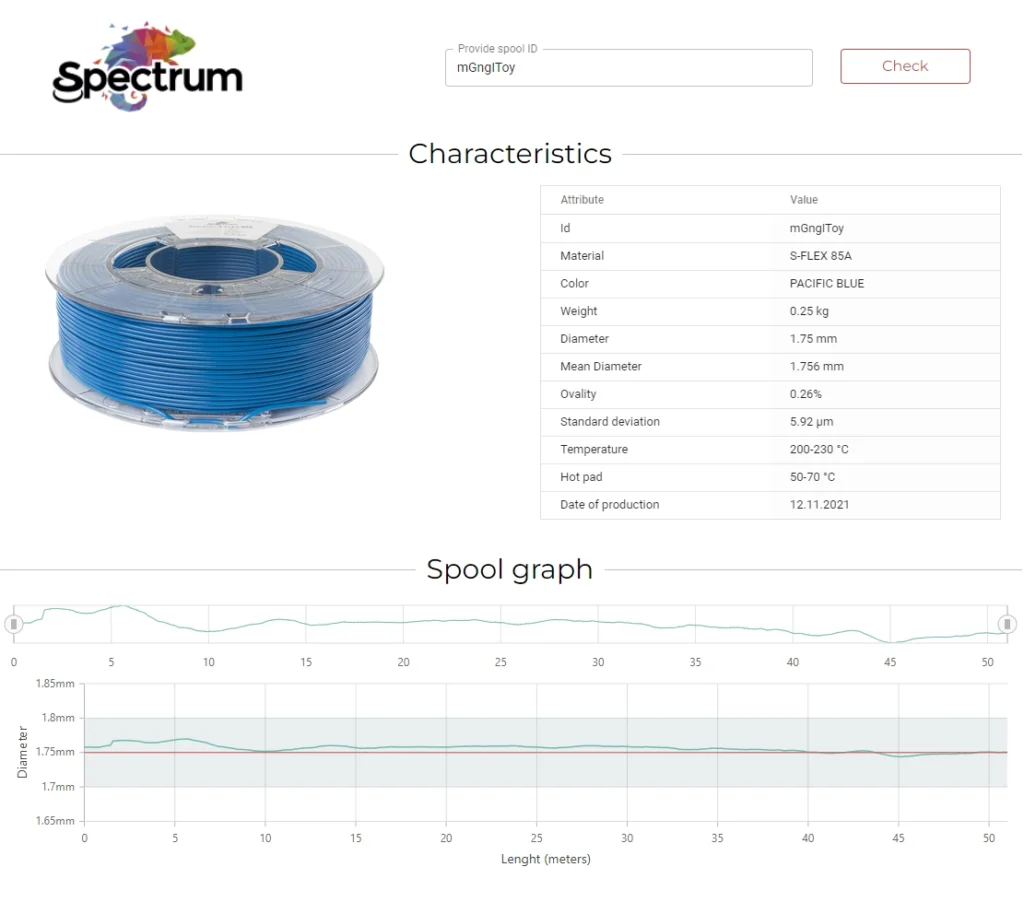

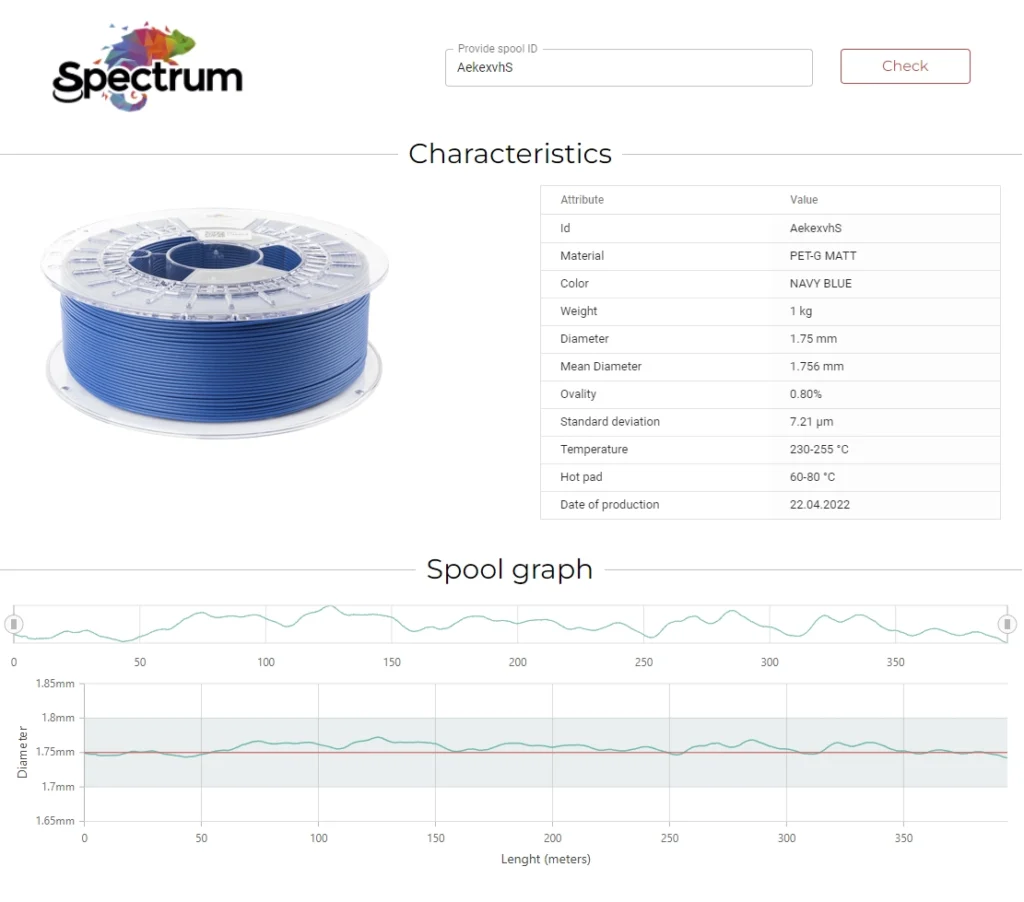

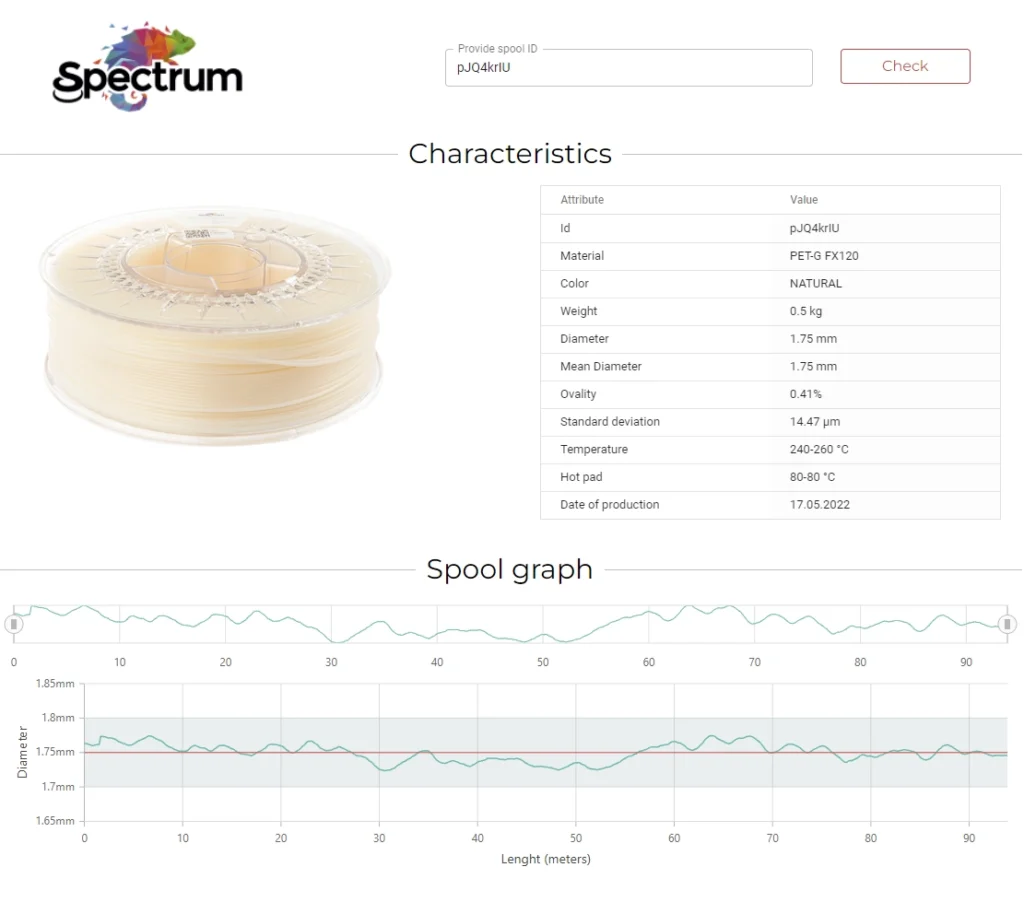

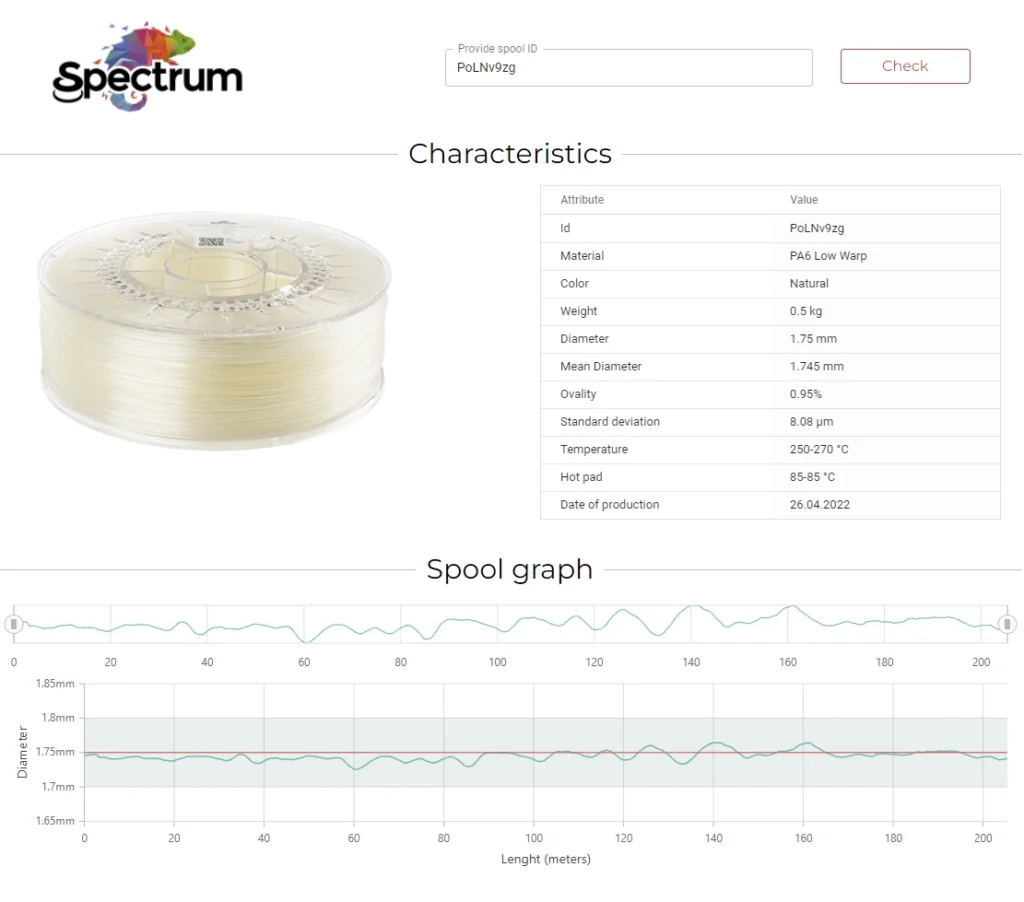

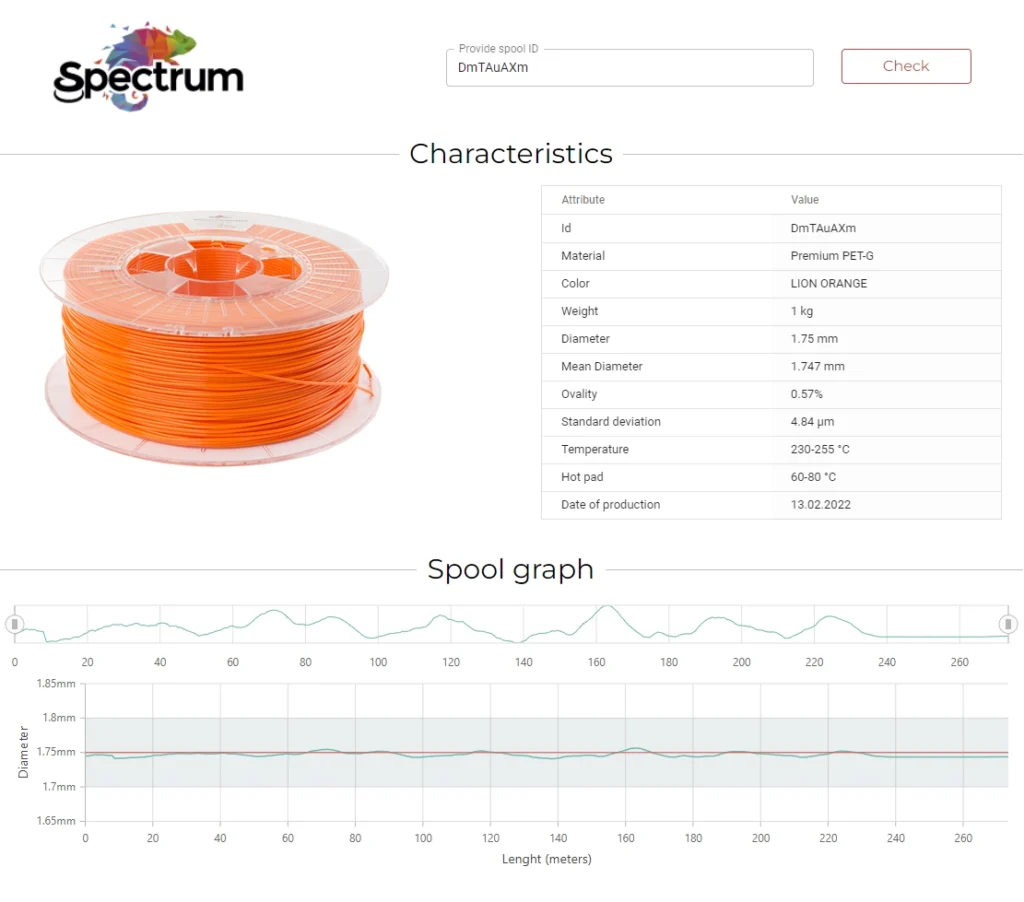

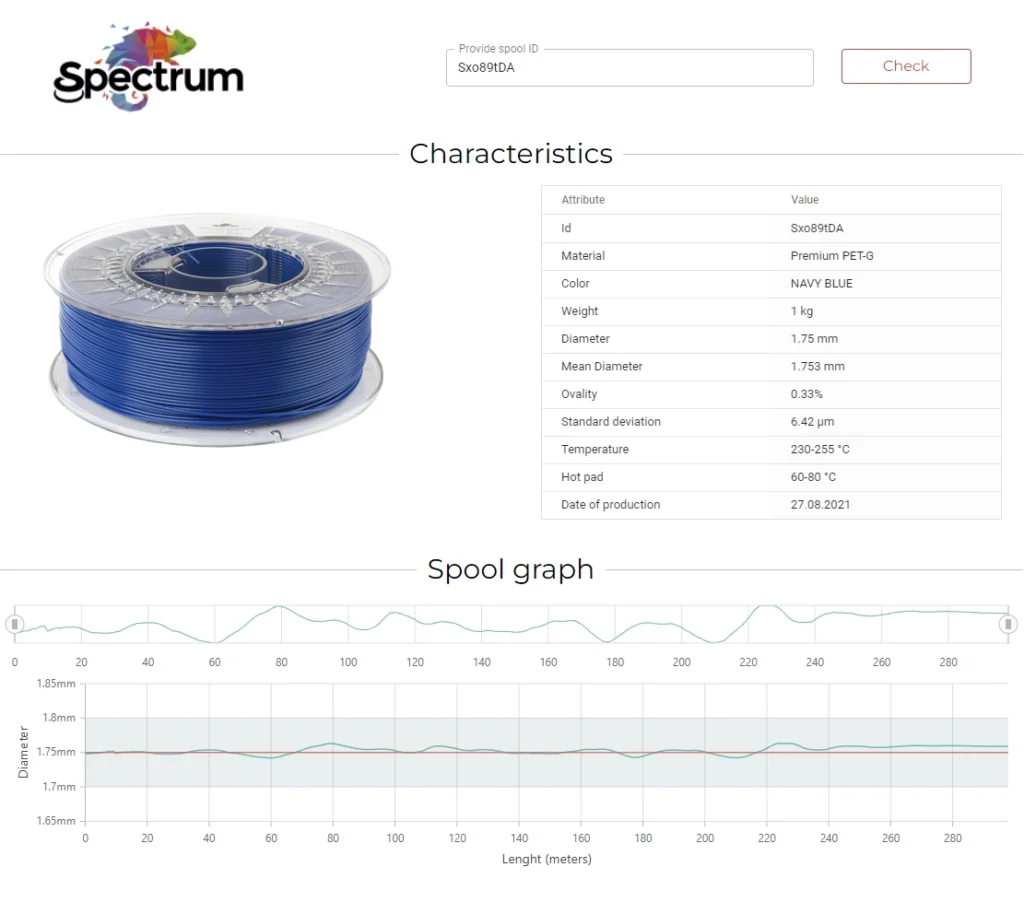

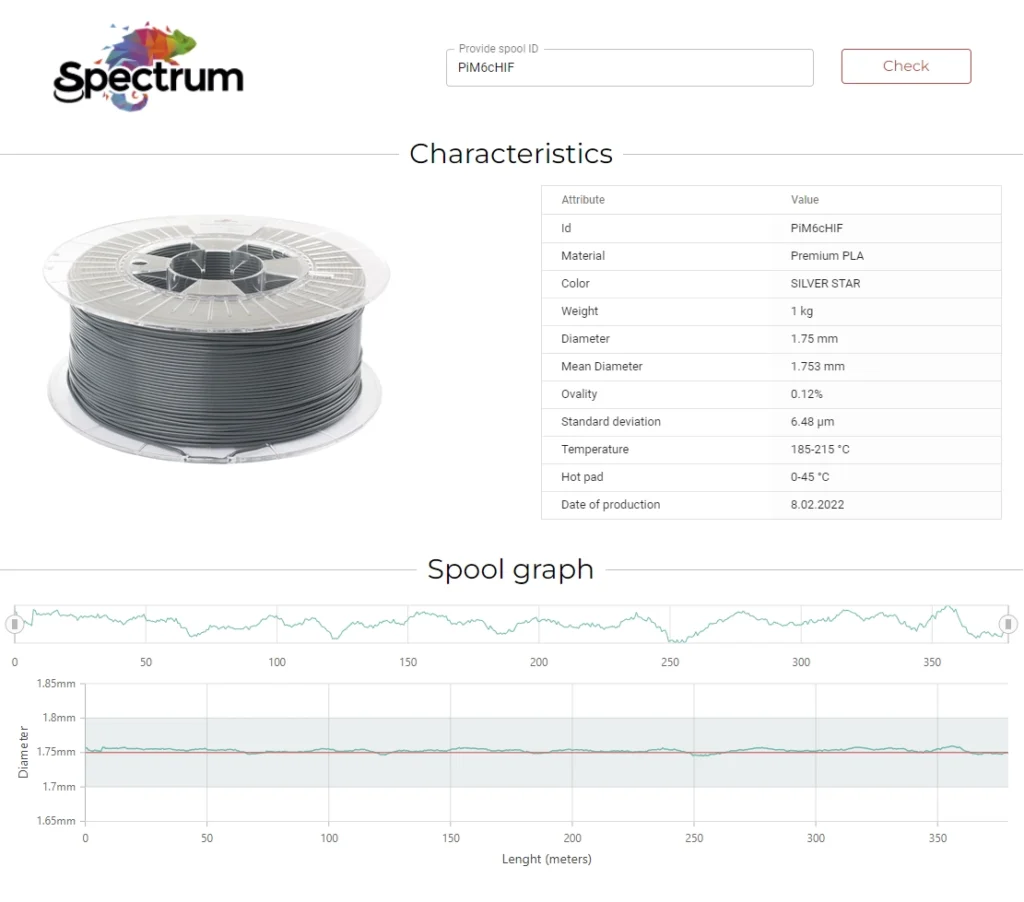

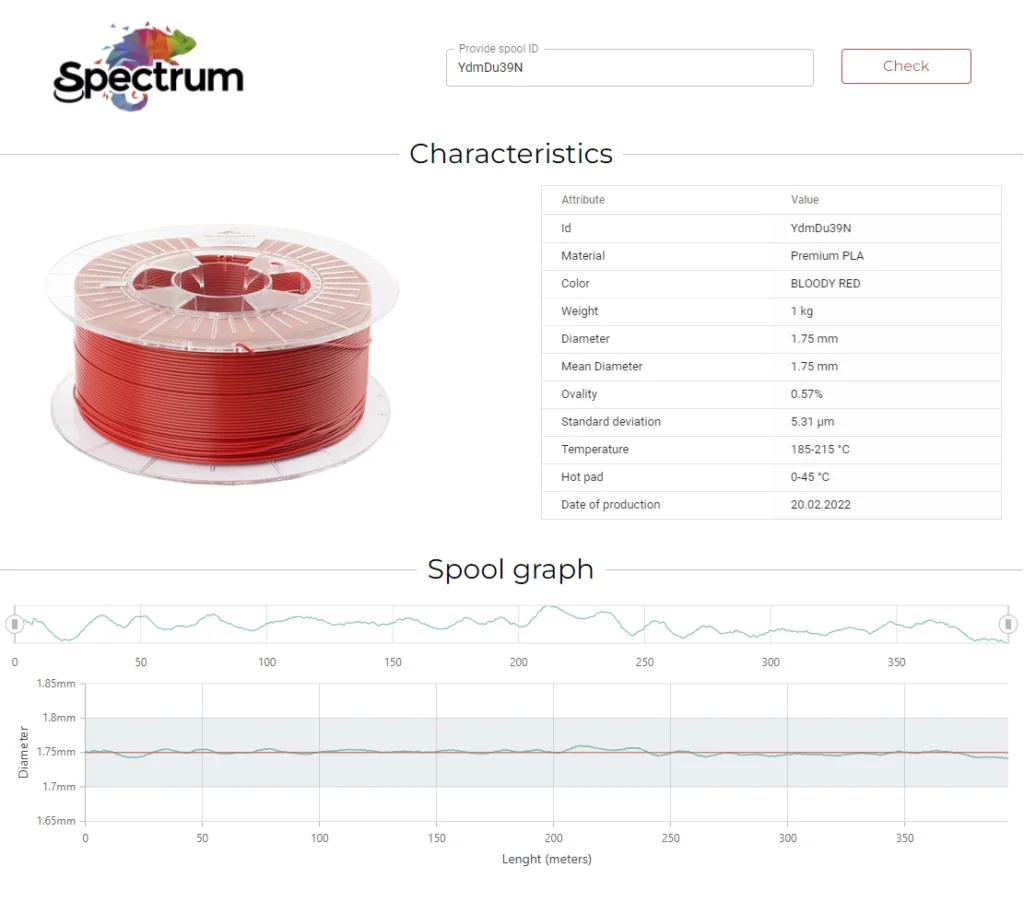

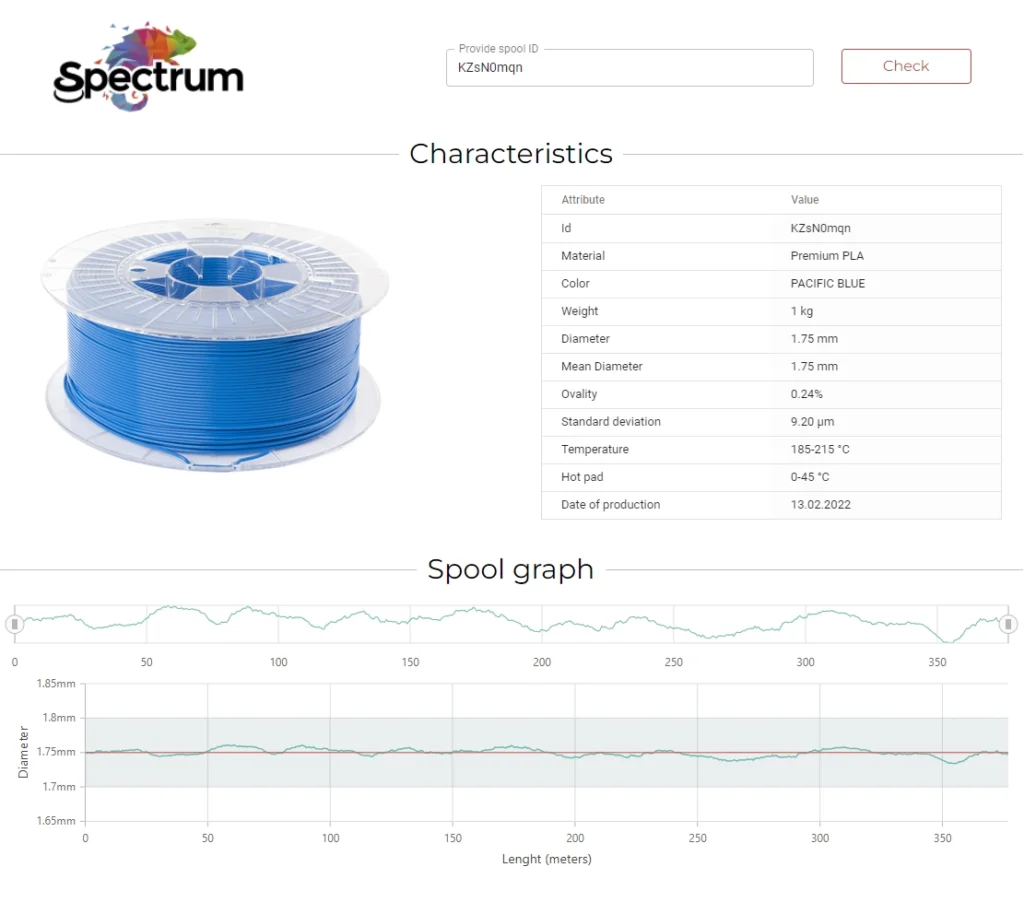

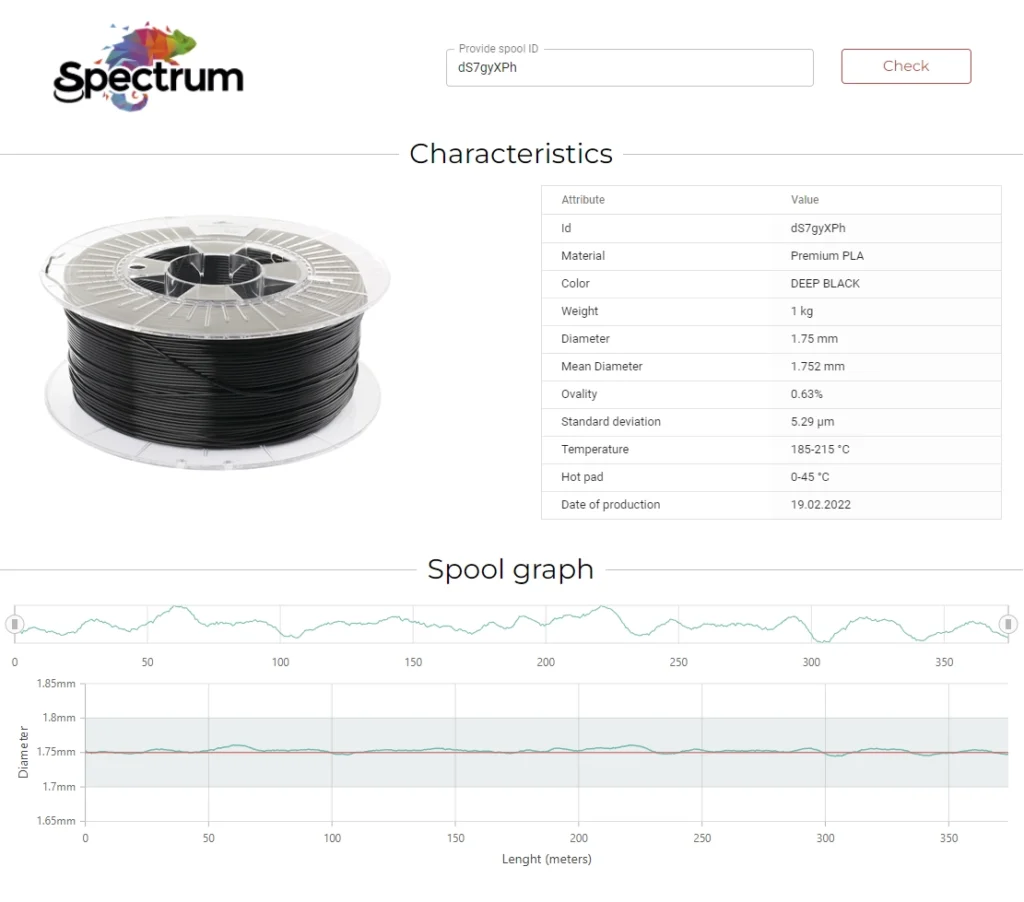

DIAMETER MEASUREMENT

During the production filament is being continuously measured in 2 axis with 0.8µm accuracy. To be sure that the measurement result is reliable we use certified laser meter devices designed by worldwide known and reputable Swiss company. In the final step collected data is transported to our database what enables end-user to check diameter online. Precise survey guarantees that our products meet rigorous market requirements.

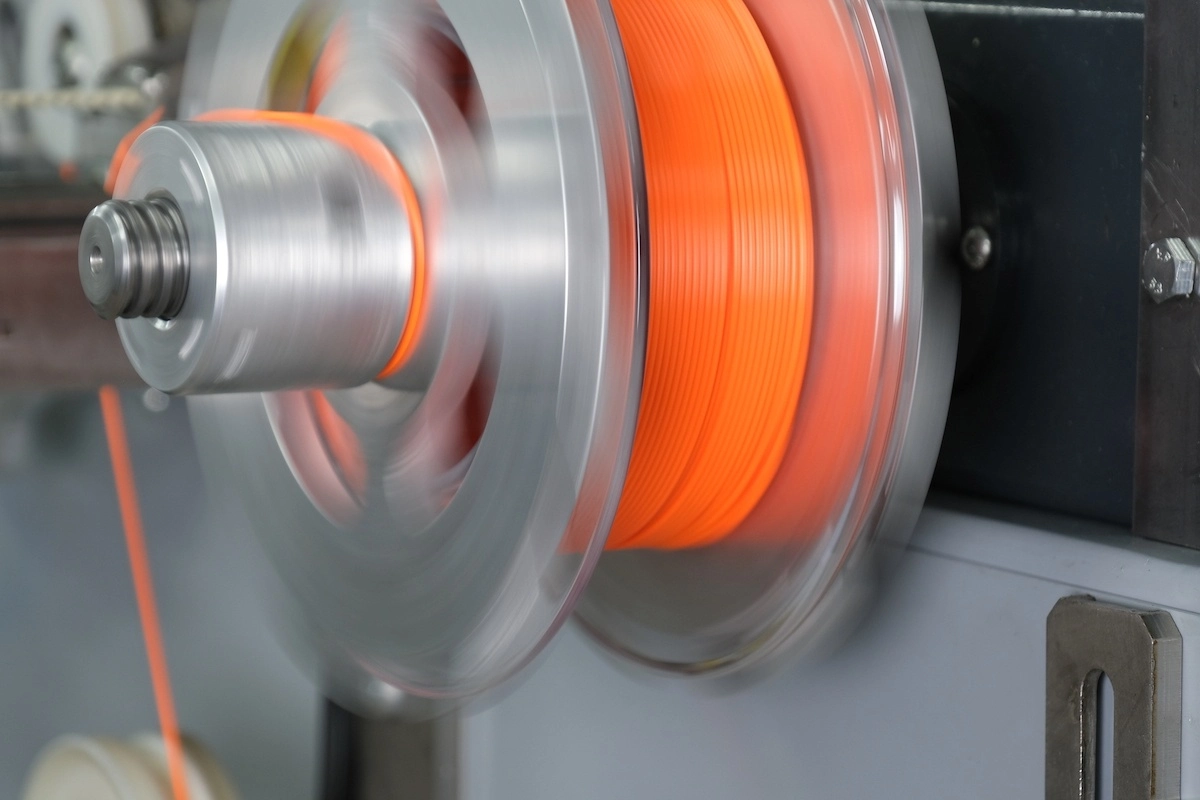

Winding quality is often underestimated, but everyone knows how important that factor is when it comes to 3D printing. Tangling of filament can be avoided only when spool is neat and tidy, that is why we pay attention to that very last step of production process.

PACKING

Each filament spool is vacuum packed inlcuding silica gel desiccant. For vacuum packaging we use foil with ZIP lock, what allows end-user to pack the filament precisely after using and prevent moisture absorption. Each spool contains information on the type of material, diameter and recommended printing temperature. At the end filament is placed in a cardboard box, which is additionally foiled.